Total Corrosion Resistance:

Impervious to H₂S, CO₂, saltwater, and other corrosive elements, eliminating internal and external corrosion.

Smarter, Faster, Safer: The Future of Pipeline Technology is Here

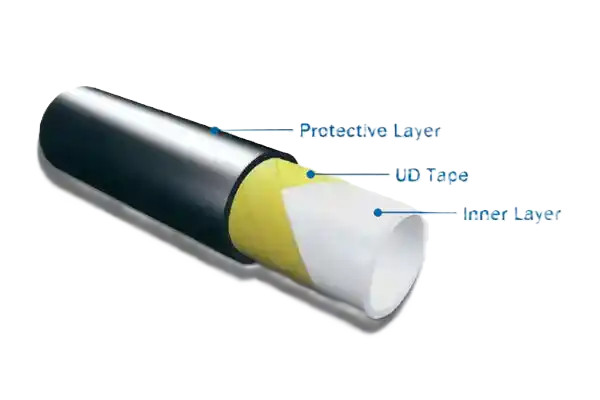

Our Composite Pipe Solution is more than just a product; it is a comprehensive, game-changing approach to flowline and injection line infrastructure. It is designed for rapid deployment, exceptional corrosion resistance, and long-term reliability, enabling you to bring production online faster and maintain it with confidence